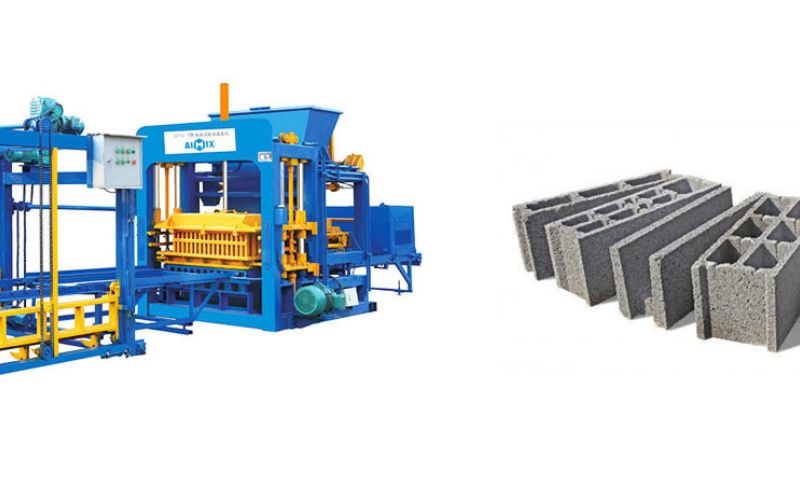

Fly ash brick-making machines have become increasingly popular in the construction industry due to their numerous benefits over traditional clay bricks. These machines utilize fly ash, a byproduct of coal-fired power plants, to produce durable and eco-friendly bricks that are not only cost-effective but also contribute to sustainable building practices.

As a business owner or a construction professional, understanding the price of fly ash brick-making machines is crucial when planning your investments and operations. This article will provide you with a comprehensive guide to navigating the world of fly ash brick-making machine prices, helping you make an informed decision that aligns with your business needs.

The Importance of Fly Ash Brick-Making Machines

Fly ash brick-making machines have revolutionized the construction industry by offering a viable alternative to traditional clay bricks. These machines produce bricks that are not only stronger and more durable but also more environmentally friendly. Fly ash bricks are known for their resistance to weathering, fire, and termites, making them a preferred choice for a wide range of construction projects.

Moreover, the utilization of fly ash, a waste product from coal-fired power plants, in the brick-making process helps to reduce the environmental impact of construction activities. By repurposing this industrial byproduct, fly ash brick-making machines contribute to the circular economy and promote sustainable building practices.

Factors Affecting the Price of Fly Ash Brick-Making Machines

The price of fly ash brick-making machines can vary significantly depending on several factors. Understanding these factors can help you make a more informed decision when purchasing a machine for your business.

- Machine Capacity: The production capacity of the fly ash brick-making machine is a significant factor in determining the price. Machines with higher output volumes generally have a higher price tag.

- Automation Level: Fly ash brick-making machines can range from semi-automatic to fully automatic. Fully automated machines tend to be more expensive due to their advanced features and increased efficiency.

- Brand and Reputation: The brand name and reputation of the manufacturer can also influence the price of the machine. Well-established brands with a proven track record of quality and reliability often command a higher price.

- Additional Features: Some fly ash brick-making machines come equipped with additional features, such as advanced molding systems, curing chambers, or integrated packaging solutions. These extra features can increase the overall cost of the machine.

- Location and Shipping Costs: The geographical location of the manufacturer and the shipping costs to your business premises can also impact the final price of the fly ash brick-making machine.

- After-Sales Support: The level of after-sales support and maintenance services provided by the manufacturer can also be a factor in the machine’s price.

Understanding these factors can help you evaluate the various options available in the market and make a more informed decision that aligns with your budget and business requirements.

Understanding the Different Types of Fly Ash Brick-Making Machines

Fly ash brick-making machines come in a variety of types, each with its own unique features and specifications. Familiarizing yourself with the different options can help you select the most suitable machine for your needs.

- Semi-Automatic Machines: These machines require manual intervention for certain steps, such as material feeding or brick removal. They are generally more affordable than fully automatic machines but may have lower production capacities.

- Fully Automatic Machines: Fully automatic fly ash brick-making machines handle the entire production process, from material feeding to brick ejection, with minimal human intervention. These machines offer higher production rates and increased efficiency, but they come at a higher price point.

- Hydraulic Machines: Hydraulic fly ash brick-making machines use a hydraulic system to apply pressure and shape the bricks. They are known for their durability and consistent brick quality, but they tend to be more expensive than other types.

- Vibration-Based Machines: Vibration-based fly ash brick-making machines use vibration to compact the fly ash mixture, resulting in a more uniform brick structure. These machines are generally more affordable but may have lower production capacities.

- Extruder-Based Machines: Extruder-based fly ash brick-making machines use a screw-type mechanism to extrude the fly ash mixture into the desired brick shape. These machines are known for their high production rates but can be more costly.

Carefully evaluating the specific requirements of your business, such as production volume, available space, and budget, can help you determine the most suitable type of fly ash brick-making machine for your needs.

Comparing Prices and Specifications of Fly Ash brick-making Machines

When it comes to purchasing a fly ash brick-making machine, it’s important to compare the prices and specifications of various models to ensure you get the best value for your money. Here’s a table that provides a general overview of the price ranges and key specifications for different types of fly ash brick-making machines:

| Machine Type | Price Range (INR) | Production Capacity (Bricks/Hour) | Power Consumption (kW) | Automation Level |

|---|---|---|---|---|

| Semi-Automatic | 5 Lakhs – 15 Lakhs | 3,000 – 10,000 | 5 – 15 | Semi-Automatic |

| Fully Automatic | 15 Lakhs – 50 Lakhs | 10,000 – 30,000 | 15 – 30 | Fully Automatic |

| Hydraulic | 20 Lakhs – 60 Lakhs | 8,000 – 20,000 | 10 – 25 | Fully Automatic |

| Vibration-Based | 8 Lakhs – 20 Lakhs | 5,000 – 15,000 | 7 – 18 | Semi-Automatic |

| Extruder-Based | 25 Lakhs – 75 Lakhs | 15,000 – 40,000 | 20 – 40 | Fully Automatic |

Please note that these are approximate price ranges and specifications, and the actual costs and features may vary depending on the manufacturer, model, and additional customizations.

Tips for Finding the Best Deals on Fly Ash Brick-Making Machines

To ensure you get the best deal on a fly ash brick-making machine, consider the following tips:

- Research the Market: Thoroughly research the market to understand the current trends, pricing, and available options from various manufacturers.

- Compare Quotes: Obtain quotes from multiple reputable suppliers and compare the prices, features, and after-sales support to find the best value.

- Negotiate: Don’t be afraid to negotiate with the suppliers, as they may be willing to offer discounts or additional services to secure your business.

- Explore Financing Options: Look into financing options, such as loans or leasing, which can help you spread the cost of the machine over a more manageable period.

- Consider Used or Refurbished Machines: Exploring the market for used or refurbished fly ash brick-making machines can sometimes provide a more cost-effective solution, especially if the machine is in good condition and comes with a warranty.

- Time Your Purchase: Keep an eye on market trends and seasonal fluctuations, as the prices of fly ash brick making machines may vary depending on the demand and supply dynamics.

By following these tips, you can increase your chances of finding the best deals on fly ash brick making machines that meet your business requirements and budget.

Evaluating the Quality and Durability of Fly Ash Brick-Making Machines

When investing in a fly ash brick-making machine, it’s crucial to evaluate the quality and durability of the equipment to ensure a long-lasting and reliable performance. Here are some factors to consider:

- Construction and Materials: Assess the quality of the materials used in the machine’s construction, such as the frame, hydraulic components, and electrical systems. Opt for machines made with high-quality, corrosion-resistant materials that can withstand the rigors of daily use.

- Automation and Control Systems: Evaluate the sophistication and reliability of the machine’s automation and control systems. Ensure that the machine offers precise control over the brick-making process, reducing the risk of defects or inconsistencies.

- Maintenance and Servicing: Investigate the availability of maintenance and servicing support from the manufacturer. A reliable after-sales service network can help ensure the longevity of your fly ash brick-making machine.

- Energy Efficiency: Consider the machine’s energy consumption and efficiency, as this can impact your long-term operational costs and environmental impact.

- Brick Quality: Assess the quality and consistency of the bricks produced by the machine. Evaluate factors such as compressive strength, water absorption, and dimensional accuracy to ensure the bricks meet industry standards.

- Manufacturer Reputation: Research the reputation and track record of the fly ash brick-making machine manufacturer. Choose a reputable brand with a proven history of delivering high-quality and durable products.

By carefully evaluating these factors, you can make an informed decision and invest in a fly ash brick-making machine that will provide long-term value and reliability for your business.

The Benefits of Investing in a High-Quality Fly Ash Brick-Making Machine

Investing in a high-quality fly ash brick-making machine can bring numerous benefits to your business, including:

- Improved Productivity: High-quality machines with advanced features and automation can significantly increase your production capacity, allowing you to meet the growing demand for fly ash bricks more efficiently.

- Enhanced Brick Quality: Sophisticated machines with precise control systems can produce bricks with superior quality, consistency, and durability, giving you a competitive edge in the market.

- Cost Savings: While the initial investment in a high-quality fly ash brick-making machine may be higher, the long-term cost savings in terms of energy efficiency, reduced maintenance, and lower production costs can make it a wise investment.

- Sustainability and Environmental Impact: By utilizing fly ash, a waste product, in the brick-making process, you can contribute to a more sustainable construction industry and reduce the environmental footprint of your business.

- Improved Brand Reputation: Offering high-quality, eco-friendly fly ash bricks can enhance your brand’s reputation and appeal to environmentally conscious customers and construction professionals.

- Competitive Advantage: Investing in a state-of-the-art fly ash brick-making machine can give you a competitive advantage by allowing you to offer superior products and faster delivery times compared to your competitors.

By weighing the benefits against the initial investment, you can make a well-informed decision that aligns with your business goals and long-term sustainability.

How to Choose the Right Fly Ash Brick-Making Machine for Your Business

Selecting the right fly ash brick-making machine for your business requires careful consideration of various factors. Here’s a step-by-step guide to help you make the best decision:

- Assess Your Business Needs: Evaluate your current and future production requirements, the available space in your facility, and the specific features you need in a fly ash brick-making machine.

- Determine the Desired Production Capacity: Consider the size of your target market, the demand for fly ash bricks, and your growth plans to determine the appropriate production capacity for your machine.

- Evaluate the Automation Level: Decide whether a semi-automatic or fully automatic machine best suits your operational needs and the level of human intervention you’re comfortable with.

- Consider the Machine’s Features: Analyze the various features offered by different fly ash brick-making machines, such as molding systems, curing chambers, and packaging solutions, to ensure they align with your requirements.

- Assess the Machine’s Efficiency: Look for machines with high energy efficiency, low power consumption, and minimal waste to optimize your operational costs and environmental impact.

- Prioritize Quality and Durability: Invest in a machine from a reputable manufacturer that uses high-quality materials and offers robust after-sales support to ensure long-term reliability and performance.

- Explore Financing Options: Evaluate the available financing options, such as loans or leasing, to determine the most financially viable solution for your business.

- Conduct a Cost-Benefit Analysis: Weigh the initial investment against the long-term benefits, including increased productivity, improved brick quality, and cost savings, to ensure the machine aligns with your budget and business goals.

By following this comprehensive approach, you can make an informed decision and select the fly ash brick making machine that best fits your business needs and budget.

Conclusion

Investing in a fly ash brick making machine is a crucial decision for any construction-related business. By understanding the factors that influence the price of these machines, evaluating the different types available, and considering the long-term benefits of a high-quality investment, you can make an informed decision that will positively impact your business’s productivity, profitability, and sustainability.

Remember, the price of a fly ash brick making machine should not be the sole determining factor. Focus on finding the right balance between cost, quality, and features that will provide the greatest value for your business in the long run. With careful research, negotiation, and a strategic approach, you can find the perfect fly ash brick making machine that meets your needs and budget.

If you’re ready to take the next step in your fly ash brick making journey, contact us today to discuss your specific requirements and explore the best options for your business. Our team of experts is here to guide you through the process and help you find the perfect fly ash brick making machine that will take your operations to new heights.